KEY FIGURES

4 specialised divisions

Manufacturing, distribution, technology, training :

Forézienne has structured its expertise to better support professionals at every stage.

The historic heart of the company, Forézienne MFLS designs, manufactures and refurbishes high-precision cutting tools for woodworking professionals. Quality, know-how and innovation are at the heart of its expertise.

Specialising in sales of tools and equipment for the woodworking industry, Forézienne Distribution is offering a a wide range of products, with personalised technical advice.

A group driven by innovation and performance

Forézienne's DNA is based on a constant desire to innovate and progress. Thanks to regular investment in research and development, we design sustainable, high-performance solutions tailored to our partners' current and future challenges.

Our products are designed to guarantee precision, durability and respect for materialswith a single objective: optimising the performance of woodworking professionals.

In 2021, to strengthen our strategic position in our markets, we have structured our expertise around four complementary centres.Each entity benefits from the synergy of the Group, to provide global and coherent expertise.

Our values, at the heart of our commitment

Passion & Engagement

Esprit d'équipe & satisfaction client

Passing on know-how is central to our culture. That's why we've created the Forézienne Academy, a training centre for our teams, partners and customers, so that together we can move towards excellence.

innovation & performance

Changes in the market are opportunities for us to innovate. The synergy between our business units stimulates the development of ever more effective solutions, serving the performance of our customers and the progress of our teams.

Durabilité & environnement

As a committed player in the timber industry, Forézienne is committed to eco-responsible resource management. From the design of our tools to the organisation of our workshops, we innovate to reduce our environmental impact and promote a sustainable future.

French company

" We are proud to have preserved our local roots.

We are convinced that French industry is a guarantee of quality.

It is these solid foundations that empower us today to forge strong partnerships with every player in the industry. "

Christian Sénégas.

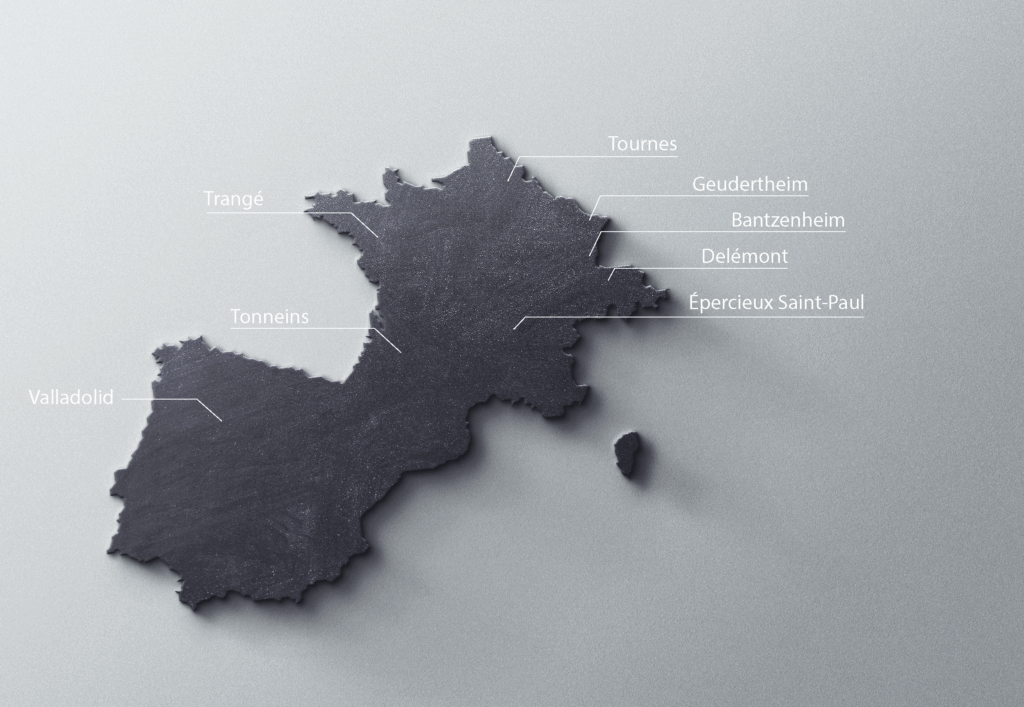

Our locations and subsidiaries: a network built to support you better

The Forézienne Group comprises a parent company, two subsidiaries, and five satellite workshops.

Forézienne relies on a network of production, distribution and service sites in France and abroad.

This strategic location enables us to guarantee proximity, responsiveness and customised support for each and every one of our customers.

INTERNATIONAL PRESENCE

Forézienne is present on the five continents thanks to a solid network of distributors and partners. This global presence enables us to offer tailored solutions to the needs of our customers, all over the world.

Our expertise and our responsiveness provide local service performance, whatever the local requirements.

An international project?

Our export team is here to help.

Contact us now using our form.

OUR HISTORY

2024

OPENING OF THE FIFTH ATELIER-RELAIS IN BANTZENHEIM (68)

To meet the expectations of our international customers, we have opened a fifth relay workshop in Bantzenheim. This strategic location strengthens our proximity to the Swiss, German and Luxembourg markets, improving our responsiveness and consolidating our local presence.

2023

OPENING OF THE FOURTH ATELIER-RELAIS IN TOURNES (08)

Inauguration of the fourth relay workshop in Tournes, specially designed to meet the needs of customers in the north of France and promote the region's economic development.

Discover our catalogues

Easily access our complete range of products and services for the wood industry.

Detailed technical data sheets for each tool and application.

OUR BRANDS

Discover partner brands de Forézienne, classified by business sector to better meet your needs.

Whether you work in a sawmill, joinery, carpentry or in the wood industry, it's easy to find the equipment and tools you need. tailored to your business. Each brand has been selected for its expertise, guaranteeing innovation, durability and performance.

OUR PARTNERS & SPONSORS

Forézienne thanks to a network of partners and sponsors who share our values of high standards, innovation and expertise. Let's work together, we are building a more efficient, responsible and sustainable timber industry.