From Craftsmanship to Industry

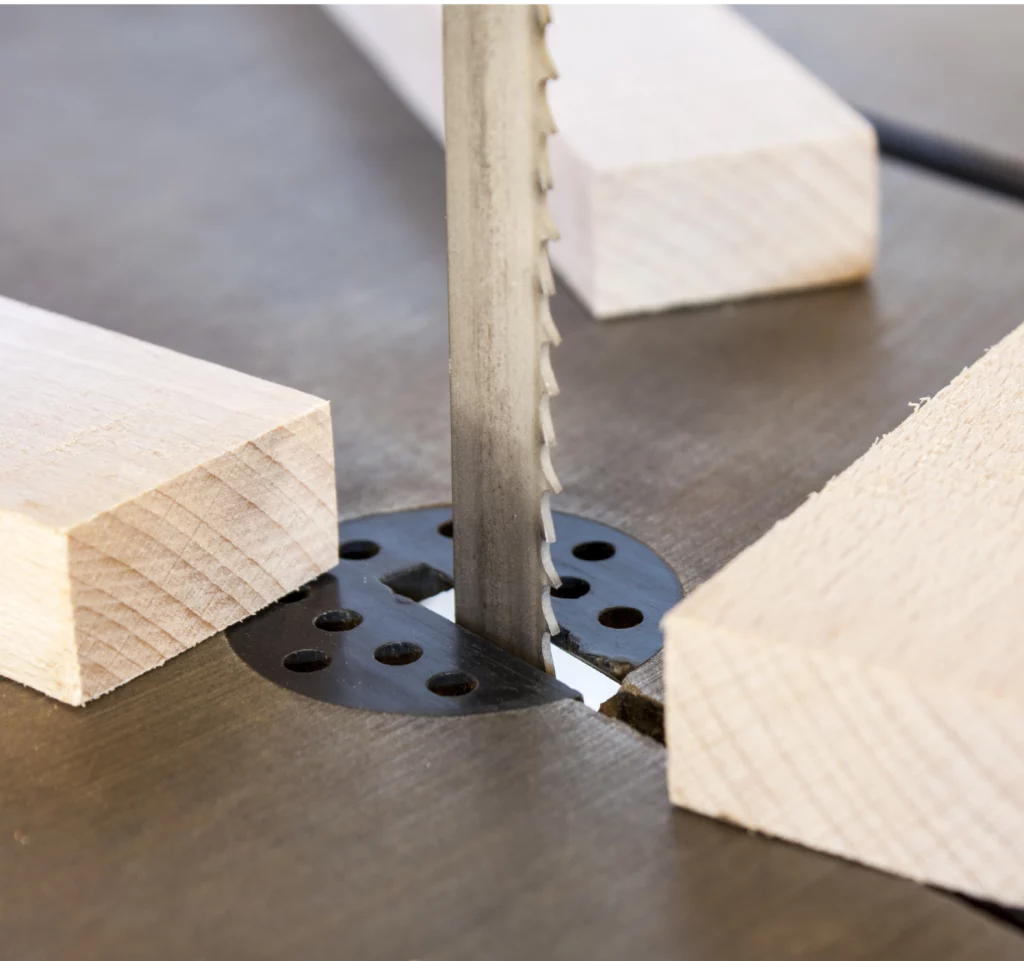

Mastering secondary wood processing

From machining to the finished product, optimize every finish

Forézienne MFLS supports secondary processing professionals with a comprehensive offering: high-precision cutting tools, suitable equipment, maintenance services, and targeted technical training.

We help enhance your productivity, the quality of your finishes, and the durability of your equipment.

Why trust Forézienne MFLS ?

For more than 50 years, Forézienne MFLS has been supporting wood-processing professionals—both in France and around the world.

Our commitment rests on three essential pillars:

- High-precision tools to guarantee consistent cutting quality.

- Comprehensive technical service, including sharpening, maintenance, and continuous performance improvement.

- Dedicated expertise in secondary wood processing, with bespoke training, technical audits, and close-support.

Expertise and know-how

50+ years serving wood industry professionals.

100% french made

French production, synonymous with quality and responsiveness

CUSTOM SOLUTIONS

Tools and services designed for your specific production lines

trusted partner

Present worldwide to support you sustainably

AN INTERNATIONAL PRESENCE

Bloc

push the limits of wood finishing

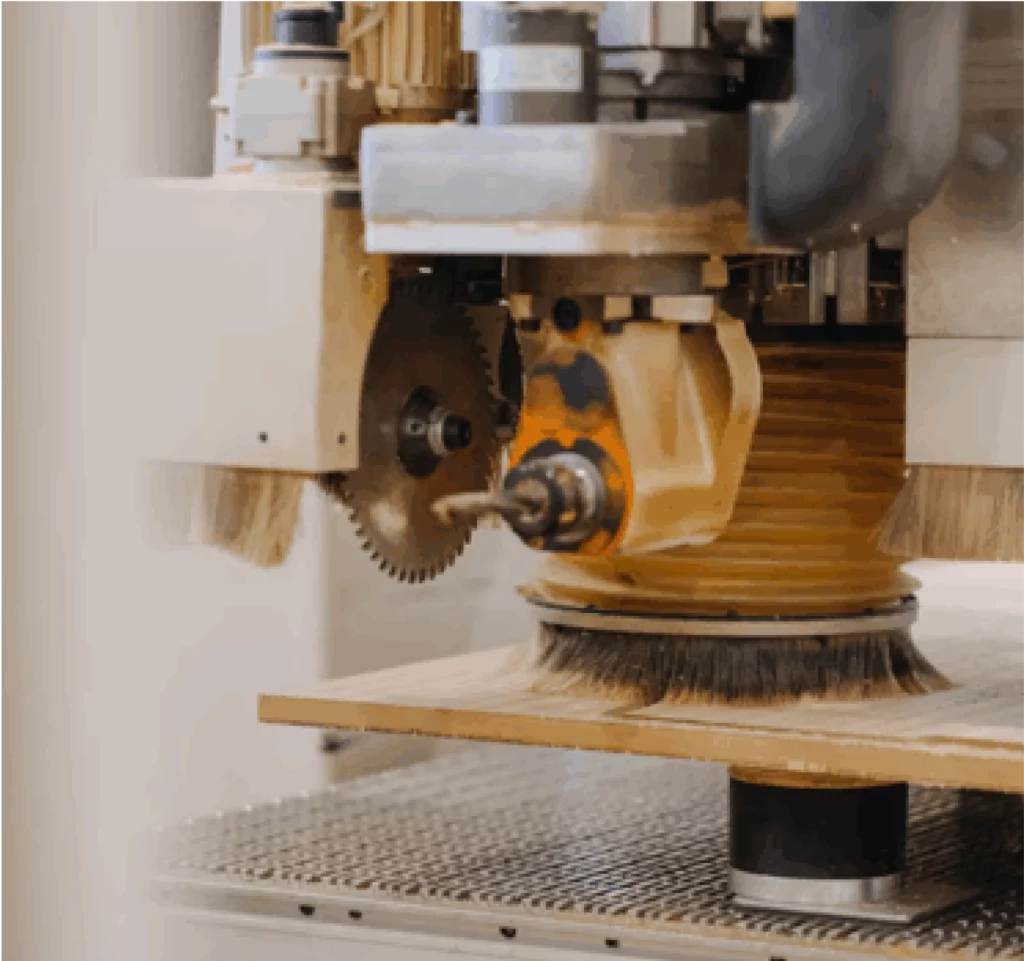

ELBÉ, the high-performance machining solution made in France.

Since 1985, ELBÉ has been designing and manufacturing wood machining solutions closely aligned with the needs of craftsmen and industrial clients. With its hands-on expertise and continuous innovation, the brand is now a reference player in planing, profiling, and precision machining.

Since 2019, ELBÉ has been part of the Forézienne group, benefiting from enhanced logistical support, an extranet platform, and a shared customer service, while maintaining 100% French know-how.

The company relies on a modern machine fleet, an active R&D department, and a passionate team to offer standard or custom-designed tools, combining performance, consistent quality, and safety. Among its innovations are the Precis Cut, the The Artist helical tool holder, and the Elistar, recognized for their efficiency and ergonomics.

ISO 9001 and 14001 certified, ELBÉ is committed to a rigorous and responsible quality approach, with particular attention to the environment.

As a partner of secondary wood processing professionals, ELBÉ embodies a reliable and sustainable technical approach, built on precision, innovation, and industrial expertise.

European innovation for clean and durable cuts

ITA TOOLS is an innovative European manufacturer, specializing in the design and production of high-performance cutting tools for machining wood, composite materials, plastics, and non-ferrous materials.

Thanks to state-of-the-art automated production and a quality-driven strategy, ITA TOOLS offers robust, precise tools tailored to the demands of processing industries.

The company relies on state-of-the-art machines (WALTER, ANCA, DMG MORI) and rigorous quality control systems to ensure consistent reliability.

With a commercial presence in over 50 countries and a high-performance B2B platform, ITA TOOLS supports professionals at every stage of machining.

In partnership with Forézienne, ITA TOOLS brings tangible added value to secondary wood processing: optimized cutting solutions, reduced material waste, increased productivity, and enhanced safety.

Our solutions are designed for all stakeholders involved

in the processing and enhancement of raw wood:

OUR SHARPENING OFFER

Extend the life of your tools, boost performance !

Forézienne MFLS offers a comprehensive sharpening service for all types of cutting tools: diamond (PCD), carbide (HM), HSS…

IN 3 STEPS :

- Online request

- Collection by carrier

- Sharpened return, ready to use

YOUR BENEFITS

- Optimized performance and lifespan

- Monitoring and traceability

- Fewer stoppages, lower costs

OUR SERVICES AND TECHNICAL SUPPORT

Accredited Technical Training

Enhance your teams’ skills

DEDICATED TRAINING CENTER

A comprehensive support program to master your tools, improve safety, and increase efficiency across all wood cutting operations.

PERSONALIZED APPROACH

Our programs are tailored to your job profiles (operators, technicians, methods managers) under real conditions, on actual machines.

DISTRIBUTION OF COMPLEMENTARY PRODUCTS

Solutions designed to enhance the efficiency of your operations

EXTENSIVE NETWORK:

Access our products through over 600 distributors in France and internationally.

TRUSTED MARKET

We select recognized technical brands to offer you a complete range of equipment suited for secondary wood processing.

DESIGN OFFICE

Technical expertise at the service of your custom projects

CUSTOM TECHNICAL ENGINEERING :

Our design office supports you in the selection, optimization, and development of your cutting tools. we tailor each solution to your equipment and production goals.

INNOVATION & PERFORMANCE

Our experts design sustainable solutions, aligned with your technical constraints, to improve finishing quality and reduce material waste.

MAINTENANCE AND REPAIR OF CUTTING TOOLS

Lasting performance through fast and precise service

COMPLETE SERVICE :

We provide regular maintenance, repair, and re-sharpening of your tools to ensure quality cutting, consistent performance, and extended tool lifespan.

PROXIMITY / FLEXIBILITY

Thanks to our network of partner workshops, we provide rapid service across France. interventions can be one-off or scheduled according to your needs.

Discover Our Specialized Catalogs

Easily access all our products and services dedicated to secondary wood processing! Detailed technical sheets for each tool and application.

Discover

Do you also work in primary wood processing?

Forézienne supports you from the log stage, with a comprehensive range of tools and solutions for sawing, preparation, and raw wood processing.

Discover our offering dedicated to primary wood processing, developed in collaboration with ELBÉ, an expert in high-performance wood solutions.

A QUESTION?

Find the answers to the most frequently asked questions about our tools, services and solutions.