Mickael

For fast cutting in special materials. Sharp, light and durable.

Special corrosion-resistant stainless steel blade with milled and ground teeth.

TIPS : Adherence to hygienic measures during food preparation is very important. Always wash the blade with soap and water after each use. Always wear protective gloves.

cutting thickness up to 250 mm.

Ideal for cutting meat, bones, ice and frozen materials

| L | l | H | K | TS | Packaging | Code |

|---|---|---|---|---|---|---|

| 300 | 275 | 19 | 1.2 | 8.5 | 5 | CMTJS1211K-5 |

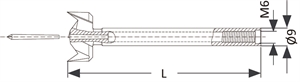

| D | S | L | Code |

|---|---|---|---|

| 10 | 9 | 100 | ZOBO762508 |

| 11 | 9 | 100 | ZOBO762509 |

| 12 | 9 | 100 | ZOBO762510 |

| 13 | 9 | 100 | ZOBO762511 |

| 14 | 9 | 100 | ZOBO762512 |

| 15 | 9 | 100 | ZOBO762513 |

| 16 | 9 | 100 | ZOBO762514 |

| 17 | 9 | 100 | ZOBO762515 |

| 18 | 9 | 100 | ZOBO762516 |

| 19 | 9 | 100 | ZOBO762517 |

| 20 | 9 | 100 | ZOBO762518 |

| 21 | 9 | 100 | ZOBO762519 |

| 22 | 9 | 100 | ZOBO762520 |

| 23 | 9 | 100 | ZOBO762521 |

| 24 | 9 | 100 | ZOBO762522 |

| 25 | 9 | 100 | ZOBO762523 |

| 26 | 9 | 100 | ZOBO762524 |

| 27 | 9 | 100 | ZOBO762525 |

| 26 | 9 | 100 | ZOBO762526 |

| 29 | 9 | 100 | ZOBO762527 |

| 30 | 9 | 100 | ZOBO762528 |

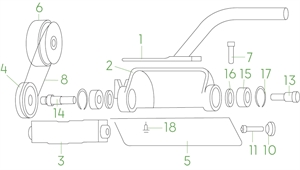

Related products

- Reducers

- Extensions and shank

- Depth stop

- Carbide drilling system 3 Ø 15-30 mm

- Carbide drilling system 3 Ø 31-50 mm

- Chrome steel drilling system 3 Ø 15 - 30 mm

- Chrome steel drilling system 3 Ø 31-50 mm

- Chrome steel drilling system 3 Ø 50 - 100 mm

- Chrome steel drilling system 3 Ø 101 - 130 mm

- Centering point and pilot drill

- Guide pin Ø 15 - 50 mm

- Set of system 3 drill bits

- Depth stop

- Countersink set

- Centering point and pilot drill

- Guide pin

- Extensions and shanks

- Reducing sleeve

- Depth stop

Diameter of holes: 4, 5, 6, 7, 8, 10, 12 mm

| Code |

|---|

| CMT552-GUIDE |

Related products

| Code |

|---|

| CMT552-EX14 |

Related products

Turn on the drilling machine to start tool rotation.

Begin drilling approximately at a 30° angle – this is the angle measured between the hole saw and the working surface.

This technique will prevent tool slippage, allow for perfect centering and increase cutting precision. To gain improved stability through the drilling process, it is advised to rest the drilling machine on the working surface.

Continue the cut vertically, accompanying the tool in an orbital motion. This will favor better cooling and chip evacuation. (If you are using a guide, begin the cut vertically, then lift the guide and continue cutting in an orbital motion). This tool is not a drill bit. Attempting to bore holes perfectly perpendicular to the work surface on a frequent basis will drastically reduce the life of the tool. Using water as a cooling agent may help extend the life of the hole saw. The percussion/hammer action mode must be turned off when using these hole saws.

| d | D | L | S | Code |

|---|---|---|---|---|

| 6 | 60 | 35 | M14 | CMT552-506 |

| 8 | 60 | 35 | M14 | CMT552-508 |

| 10 | 60 | 35 | M14 | CMT552-510 |

| 12 | 60 | 35 | M14 | CMT552-512 |

| 20 | 60 | 35 | M14 | CMT552-520 |

| 25 | 60 | 40 | M14 | CMT552-525 |

| 28 | 60 | 40 | M14 | CMT552-528 |

| 35 | 60 | 40 | M14 | CMT552-535 |

| 43 | 60 | 40 | M14 | CMT552-543 |

| 68 | 60 | 40 | M14 | CMT552-568 |

Related products

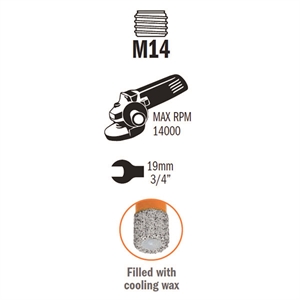

TECHNICAL FEATURES :

- Special side holes.

- Fast & easy center drill change.

- Thin cutting edge.

Diamond grit premium grade

Well-shaped and extremely strong cubo-octahedral inclusion-free heat-resistant crystals delivers fast, clean cuts up to 10 times longer life.

Diamond grit edge hole saws have been specially developed for professionals that need to drill in extremely hard materials where it is increasingly difficult to drill with conventional hole saws. These hole saws guarantee excellent performance and superior lifetime!

Materials :

- Floor tiles (porcelain, gres, quarry).

- Wall tiles (porcelain, gres, quarry).

- Hard stones (granite, marble), Okite.

- Solid bricks.

- Sandwich materials.

- Masonry.

- Gypsum/plasterboard.

- Fiber cement board.

.

Percussion/hammer action mode must be turned off when using these hole saws. Do not use an angle grinder. Just use a high speed drilling machine (minimum 14V recommended). Always pre-drill with the center drill to achieve the best performance. Accurate drill positioning. Center drill reduces the risk of slipping.

| Code |

|---|

| CMT552-501-06 |